The MultiTest-dV is a superior motorised tensile and compression tester offering outstanding value. Designed for precision-controlled compression and tension testing the MultiTest-dV delivers easy to use controls, backed by sophisticated electronics, make it the ideal choice for a wide range of routine testing.

It improves greatly on the variability encountered with manual testers where tension and compression are applied by hand at varying speeds. By applying force at a constant speed, whilst gripping the sample in a uniform manner, the motorised MultiTest-dV significantly enhances the repeatability of test results.

Operators can perform routine batch testing with excellent throughput, minimising testing time, and benefit from the convenience associated with our motorised tensile testers.

The MultiTest-dV is available in two different configurations:

Simple tensile measurement

Test to a target displacement limit or, when using any one of the Mecmesin range of Advanced Force Gauges (AFG), to a load limit or break.

Add VectorPro Lite software to a MultiTest-dV with AFG, for data acquisition, plotting of graphs, calculation of results, plus reporting and exporting of test data.

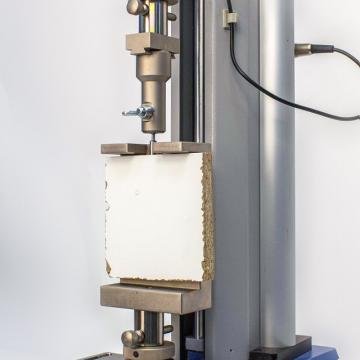

Sophisticated materials tensile measurement

Fit a dedicated ELS loadcell and connect up to VectorPro MT software to use your MultiTest-dV as an entry-level materials tester.

Control your whole test sequence with simple, step-by-step programmes. Perform both standard calculations like peak, load at displacement and more complex calculations such as Youngs Modulus, and offset yield strength.

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

Tension & Compression

Available loadcells (all measure from zero to the value indicated in the table below)

| Model | AFG 2.5 |

AFG 5 |

AFG 10 |

AFG 25 |

AFG 50 |

AFG 100 |

AFG 250 |

AFG 500 |

AFG 1000 |

AFG 2500 |

|---|---|---|---|---|---|---|---|---|---|---|

| N | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 | 500 | 1000 | 2500 |

| lbf | 0.55 | 1.1 | 2.2 | 5.5 | 11 | 22 | 55 | 110 | 220 | 550 |

| kgf | 0.25 | 0.5 | 1 | 2.5 | 5 | 10 | 25 | 50 | 100 | 250 |

|

Accuracy |

±0.1% of full scale. eg. AFG 100 has full-scale capacity of 100 N so is accurate to ± 0.1 N at any point between 0 - 100 N |

|

Resolution |

1:5000 |

| Model | ELS 2 |

ELS 5 |

ELS 10 |

ELS 25 |

ELS 50 |

ELS 100 |

100 |

200 |

ELS 250 |

ELS 500 |

500 |

1000 |

2500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N | 2 | 5 | 10 | 25 | 50 | 100 | 100 | 200 | 250 | 500 | 500 | 1000 | 2500 |

| lbf | 0.44 | 1.1 | 2.2 | 5.5 | 11 | 22 | 22 | 44 | 55 | 110 | 110 | 220 | 550 |

| kgf | 0.2 | 0.5 | 1 | 2.5 | 5 | 10 | 10 | 20 | 25 | 50 | 50 | 100 | 250 |

|

Accuracy |

± 0.5% of reading from 5-100% of the loadcell capacity. eg ELS 100 when measuring 10N is accurate to ± 0.05 N or when measuring 50N it is accurate to ± 0.25 N. |

|

Resolution |

1:25,000 |

Displacement

|

Maximum displacement |

1200 mm (0.5kN), 1000 mm (1kN), 500 mm (2.5kN) 47" (0.5kN), 39" (1kN), 20" (2.5kN) |

|

Accuracy |

±0.13mm per 300mm travel (±0.005" per 11.8" travel) |

|

Resolution |

0.001mm (0.00004") |

Speed

|

Range |

0.1 - 1200 mm/min (0.004 - 47.2"/min) |

|

Accuracy |

Better than 2% of indicated speed or ±20 µ/min, whichever is greater* |

|

Resolution |

0.1 mm/min (0.004"/min) |

Dimension

|

Crosshead travel |

1186 mm (0.5kN), 986 mm (1kN), 507 mm (2.5kN) 47" (0.5kN), 39" (1kN), 20" (2.5kN) |

|

Throat depth |

70.5 mm (2.6") |

|

Height |

1616 mm (0.5kN), 1416 mm (1kN), 941 mm (2.5kN) 67" (0.5kN), 59" (1kN), 37" (2.5kN) |

|

Width |

290 mm (11.4") (0.5kN to 2.5kN models) 11.4" (0.5kN to 2.5kN models) |

|

Depth |

414 mm (16.3") (0.5kN to 2.5kN models) |

|

Weight |

31 kg (68 lbs), 0.5kN; 27.5 kg (61 lbs), 1kN; 24 kg (53 lbs), 2.5kN |

Common specifications

|

Voltage |

230 V AC 50 Hz or 110 V AC 60 hz |

|

Operating temperature |

10 - 35°C (50 - 95°F) |

|

Humidity range |

Normal industry and laboratory conditions, non-condensing |

Communications

|

Output of test data from software to PC/printer/datalogger |

Yes, via USB |