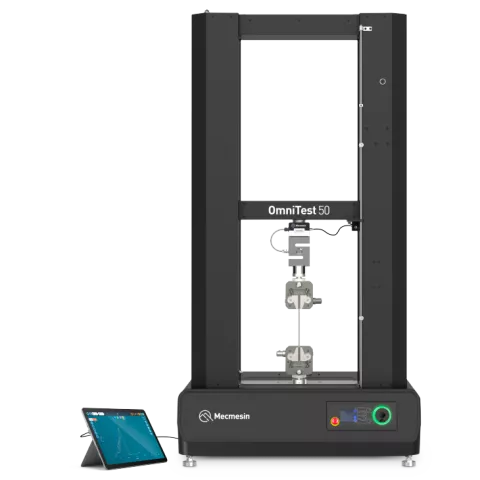

A versatile and easy to use higher-capacity universal testing machine powered by our newly developed materials testing software, VectorPro MT.

To suit your materials testing requirements the OmniTest range of universal testing machines is available as single-column (5 kN or 7.5 kN) and dual-column (10 kN, 25 kN and 50 kN) models.

As materials testers, they have been designed for versatility and ease-of-use thus appealing to users of varying skills and experience. They all fit comfortably on your bench-top, making them ideal for use in QC and R&D laboratories.

All OmniTest models are controlled by VectorPro-MT software running on a PC. They deliver both consistency and reliability by controlling the key test parameters of stress/strain, force/displacement and speed/load rate.

Whether you need to know the Young's Modulus, Offset Yield, Ultimate Tensile Strength or a whole host of other materials characteristics, the OmniTest universal testing machine has it covered for you.

The twin-column OmniTest testing system comprises five key elements:

Brochures

Got a question about this solution?

Get in touch and speak to one of our Technical Sales Engineers now...

Speak to an expert

Tension & Compression

OmniTest frame - rated capacity

| Model | 10 | 25 | 50 |

|---|---|---|---|

| kN | 10 | 25 | 50 |

| kgf | 1000 | 2500 | 5000 |

| lbf | 2200 | 5500 | 11000 |

Dimension

|

Crosshead travel |

950 mm (37.4") - 10 & 25kN models 1100 mm (43.3") - 50kN model |

|

Distance between columns |

400 mm (15.7") - 10 & 25kN models 420 mm (16.5") - 50kN model |

|

Height |

1500 mm (15.7") - 10 & 25kN models 1931 mm (76") - 50kN model |

|

Width |

826 mm (32.5") - 10 & 25kN models 864 mm (34") - 50kN model |

|

Depth |

542 mm (21.3") - 10 & 25kN models 572 mm (22.5") - 50kN model |

|

Weight |

140 kg (309 lbs) - 10 & 25kN models 285 kg (628 lbs) - 50kN model |

Speed

|

Range |

10 kN = 0.01-1000 mm/min (0.0004 -39.4"/min) 25 kN = 0.01-1000 mm/min (0.0004 -39.4"/min) ~ 0 to 10kN = 0.01- 500 mm/min (0.0004 -19.7"/min) ~ 10 to 25kN 50 kN = 0.01- 400 mm/min (0.0004 - 15.7"/min) ~ 0 to 25kN = 0.01- 250 mm/min (0.0004 - 9.8"/min) ~ 25 to 50kN |

|

Accuracy |

At steady state: <50 mm/min = ±0.5% of indicated speed or ±0.05 mm/min (whichever is greater) 50 - 500 mm/min = ±0.2% of indicated speed >500 mm/min = ±1% of indicated speed |

|

Resolution |

0.001 mm/min (0.00004"/min) |

Displacement

|

Maximum displacement |

950 mm (37") - 10 & 25kN models 1100 mm (43") - 50kN model |

|

Accuracy |

±0.1% of indicated position or ± 0.01 mm, whichever is greater |

|

Resolution |

0.001 mm (±0.00004") |

Load

| Capacity and range | Each loadcell reads from zero to its full nominal capacity (listed below). |

| Model | ELS 2 |

ELS 5 |

ELS 10 |

ELS 25 |

ELS 50 |

ELS 100 |

ELS 250 |

ELS 500 |

|---|---|---|---|---|---|---|---|---|

| N | 2 | 5 | 10 | 25 | 50 | 100 | 250 | 500 |

| lbf | 0.44 | 1.1 | 2.2 | 55 | 110 | 220 | 550 | 1100 |

| kgf | 0.2 | 0.5 | 1 | 2.5 | 5 | 10 | 25 | 50 |

| Model | ELS-S 100 |

ELS-S 200 |

ELS-S 500 |

ELS-S 1000 |

ELS-S 2500 |

ELS-S 5000 |

ELS-S 7500 |

|---|---|---|---|---|---|---|---|

| N | 100 | 200 | 500 | 1000 | 2500 | 5000 | 7500 |

| lbf | 22 | 44 | 110 | 220 | 550 | 1100 | 1650 |

| kgf | 10 | 20 | 50 | 100 | 250 | 500 | 750 |

| Model | ELS-T 10 |

ELS-T 25 |

ELS-P 20 |

ELS-P 50 |

|---|---|---|---|---|

| kN | 10 | 25 | 20 | 50 |

| lbf | 2200 | 5500 | 4400 | 11000 |

| kgf | 1000 | 2500 | 2000 | 5000 |

|

Accuracy |

±0.5% of reading. Class 0.5 according to ISO 7500-1, eg ELS 100 when measuring 10 N is accurate to ±0.05 N or when measuring 50 N it is accurate to ±0.25 N. |

|

Resolution |

1:50,000 filtered from 24 bit |

|

Units of measurement |

mN, daN, N, kN, gf, kgf, ozf, lbf |

|

Sampling rate |

20 kHz |

|

Data-acquisition rate |

500 Hz |

Common specifications

|

Voltage |

230 V AC 50 Hz or 110 V AC 60 hz |

|

Operating temperature |

30% - 80%, non-condensing |

|

Humidity range |

Normal industry and laboratory conditions, non-condensing |