Tensile test types applications

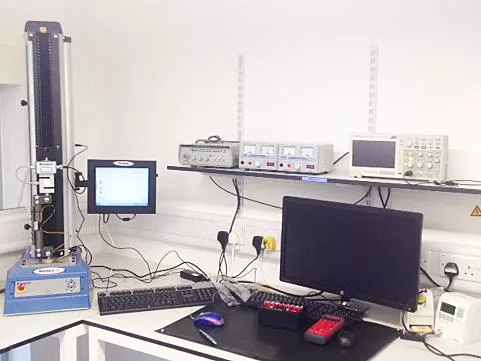

Customer examples, tensile test case studies and videos. We've pulled together some of our favourite tensile testing case studies, application examples, example videos and product introductions.

Practical applications for tensile testing

Tensile testers are used to measure the strength of products and components or the properties of materials.

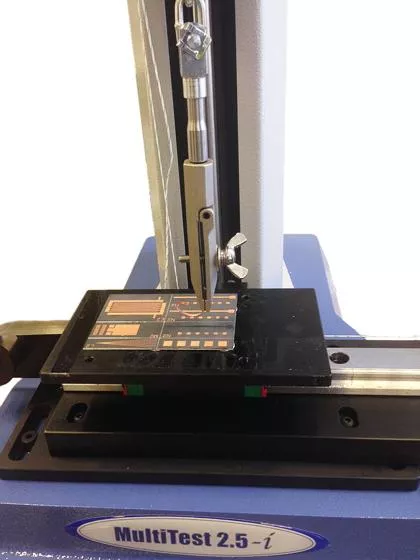

Tensile testing is commonly carried out on objects like textile attachments, welded connectors and fastenings, adhesive joints and seals.

The packaging industry for example use automated tensile testers to measure the force needed to open flip-cap containers, pull-out stoppers etc.

The application areas are almost limitless across all industries! Many applications have complementary compressive tests (eg push and pull to check opening and closing characteristics).

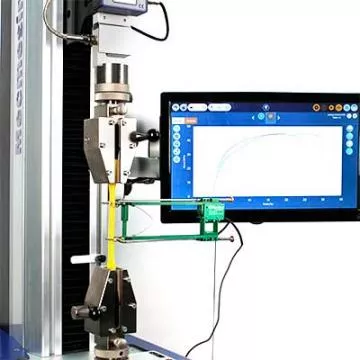

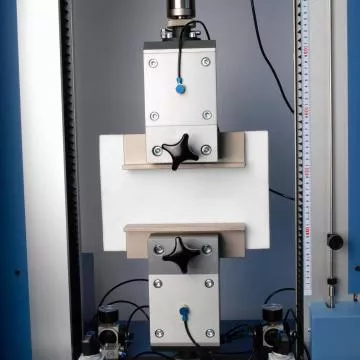

Where both tension and compression measurement of a product is required, then a tensile tester or universal testing machine (UTM) fulfils both these requirements.

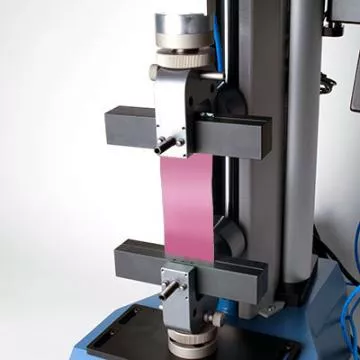

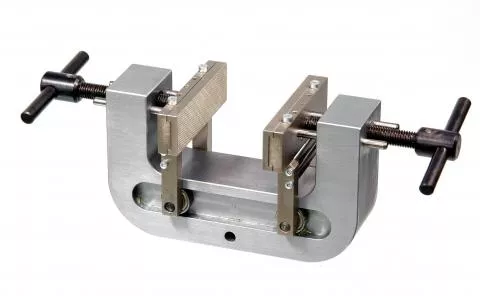

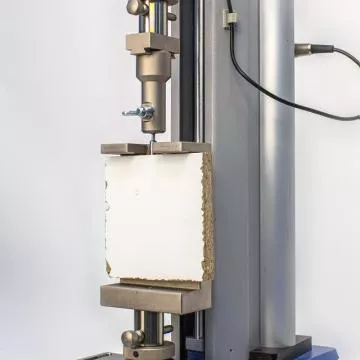

Since the shapes and features of manufactured products are so variable, and can be awkward to grip without deformation, Mecmesin regularly design and develop custom fixtures for individual products.

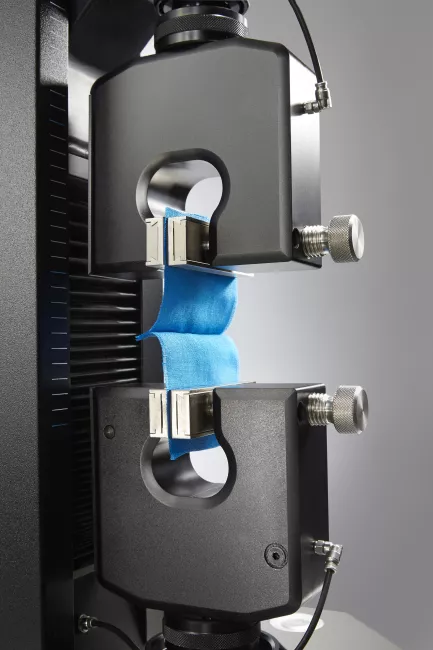

Materials testing goes further and usually requires measuring the full tensile properties of a material such as its elastic modulus, rather than just the ultimate tensile strength.

Materials testing standards will often call for the measurement of stress/strain and typically define the specimen dimensions and recommended grips to be used.